Some cast-iron products come pre-seasoned ( Lodge logic) but many need to be seasoned/reseasoned over time in order to maintain the no-stick surface and avoid marking product.

To season a cast iron product:

Proper maintenance of your cast iron cookware will allow for optimum performance and product release and help avoid discolor marks on baked product.

Pin firing is a widely used manufacturing process that allows china manufacturers to provide a fully glazed foot rather than a polished foot.

This process has the future china product going through the kiln on a mini stand which rests the greenware on “pins” so when glazed it does not stick to the kiln surface.

This process creates “pin marks” which reflect where the china rested while going through the kiln. These are completely normal, are fully vitrified, and completely non-porous.

Some examples of “pin marks” are displayed below.

Most products are dishwasher safe with the exception of those which have material bases. All products can be wiped clean using soap and warm water. Light scratches can usually be rubbed out using a damp cloth.

To enhance the richness of the slate a gentle coating of mineral oil can be applied before serving the food onto the slate. Welsh Slate is ISO14001 Certified and has stringent environmental policies in place.

| ABS | |

| Acrylonitrile | Provides heat stability, chemical resistance, and aging resistance. |

| Butadiene | Provides low-temperature property retention, toughness, and impact |

| Styrene | Adds luster, Rigidity, and processing ease. |

The combination of the above items makes ABS a very tough material, especially around various acids and chemicals and where the product must withstand abuse. Dark colors will blanche out in moisture and high heat. Used in coffee mugs, oval trays, and compartment trays.

| |

| Acrylic | Noted for its clarity, rigidity and scratch resistance. There are four types of Acrylic |

| Extrude | Least chemical resistance of all Acrylics. |

| Injection Molded | Poor chemical resistance. Used in sneeze guard shields. |

| Continuous Cast | Fair chemical resistance. Used in thermoformed product that will have food contact. |

| Cast Cell | Good chemical resistance. Used in thermoformed product that will have food contact. |

Acrylic has extremely high weatherability without yellowing or deterioration over long periods of time. It has poor chemical resistance at elevated temperatures.

| |

| Heavy Valox | Used where the weight and fell of ceramic is desired. Good in cold temperature use because of its rapid heat transfer, which is similar to ceramic, Has good high resistance (350F distortion temperature) and can be used in a microwave, but not recommended for foods with high sugar and grease contents. Excellent impact resistance, but surface hardness not as good as SAN.

|

| Polycarbonate | It has extremely high impact resistance and toughness, glass-like transparency and broad use temperature limits. It has good stain resistance, excellent surface, stiffness, and good chemical resistance. Is used in spoons, pebble bowls, pitchers, and Petal Mist dinnerware. This material is also used in some microwaveware. Its temperature use ranges from 0F to 275F.

|

| Polyethylene, High Density | Extremely chemical resistant, impact resistant, Not as rigid as SAN, used for material handling containers and storage containers where rough handling will occur. It is good in low-temperature applications (-50F). Used in bread and bun baskets, Bains Maries, and storage containers. |

| Polyethylene, Low Density | Excellent chemical resistance, toughness, impact resistance, and stress crack resistance. Low-temperature use is -40oF.

|

| Polypropylene- Copolymer | It is more rigid and more scratch resistant than polyethylene. It is very chemical resistant, durable and tough. Storage containers and Bains Maries have excellent contact clarity and have better low-temperature impact than Homopolylene. It is also used in Poly-tuf crocks for cold temperature use. |

| Polypropylene-Block Copolymer | Same characteristic as other polypropylenes, but is slightly more flexible and has a much better impact. Used in dish racks.

|

| Polystyrene, High Heat | A rigid styrene that has good clarity. Used where rigidity and Polystyrene, clarity are desired, but chemical resistance is not required. Has higher heat High Heat resistance than general purpose styrene. Used in sugar caddies and tip trays. Is a brittle and low impact material similar to SAN. |

| Polystyrene, High Impact | This is a polystyrene with rubber added to give greater impact resistance. It is not as rigid and brittle as SAN and is not chemical resistant . Used in tortilla servers. Used in tortilla servers. |

| SAN | Used where chemical resistance, toughness, and gloss are required. Gives an excellent china-like appearance. Used for table top service where chemical resistance and appearance are important. Also, has good clarity but has a slightly bluish tint. Used in Continental and Crystalline pitchers, tumblers, Classic crocks, deli crooks, octagonal crocks and some mugs. BPA Free |

| Thermoset Resins | |

| Melamine | Excellent dinnerware materials with china-like appearance. Has the best scratch resistance of the dinnerware materials with china like appearance. Has the best scratch resistance of the dinnerware materials, along with good chemical resistance, good impact resistance (will break) and broad-use temperature limits. Not recommended for microwave use. |

| Polyester - BMC | Best material for high heat applications up to 400°F. Good rigidity, chemical resistance and excellent for microwave use. This is a strong material but may break if dropped on a hard surface. Can get a range of colors with little difference in cost. Black is a poor color and white will yellow when exposed to temperatures near 400°F. Used in polyglass covers. |

| Polyester - Slurry | Used in fiberglass trays. Very durable with good depth of color. Good decoration capabilities. |

Metal marking appears as a greyish stain on dinnerware and is caused by contact with Stainless steel ( flatware, worktables, sizzle platters, platecovers, dish machine doors, etc.) that either has not been cleaned properly or is of a softer grade SS.

Metal marking is NOT from the dinnerware but rather is caused by a piece of dinnerware having the film from dirty stainless steel transferred to it. Most often this occurs by sliding the plate over an SS work surface, but it also can come from softer SS as used in knives, metal accessory pieces, or from any SS transferring the film. Often an inexperienced dish person will be caught using SS scrubbies to remove stuck on food which will also cause metal marks.

Under most conditions, this washes off in the rinse but on occasion the film remains on the dinnerware and adheres to it when the water evaporates, essentially baking it on. In many cases, it collects in scratches in the glaze, or on the foot of the piece.

In ALL cases metalmarks can be removed by using a product like lemoneze, or dip-it from Ecolab, or by using a mildly abrasive cleaner like soft scrub. Clean the product using a WHITE scrubby and the marks will readily come off.

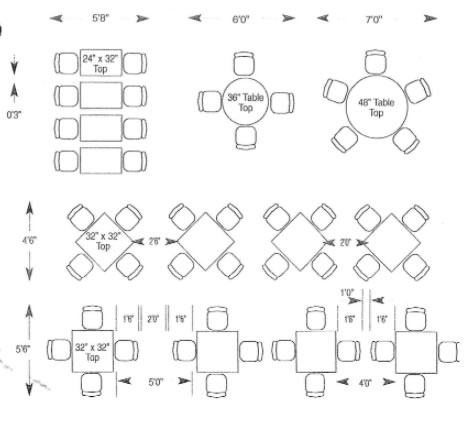

Before you begin, check your local codes and be sure to comply with the Americans with Disability Act (ADA).Take the square footage of your area and divide by the space allowance per seat to determine potential capacity. Deuce seating and wall spacing maximize the most space, although diagonal seating also saves floor space.

Note: the ADA requires a 36" clearance for aisle for dining areas; 5% of the total dining space should be accessible to wheelchair users.

| ITEM TYPE | FINE DINING | FAMILY / RESTAURANT | BAR SERVICE |

|---|---|---|---|

| Juice | 1 1/2 | 1 1/2 | 1 1/2 |

| Long Drink / Highball | 1 1/2 | 1 1/2 | 1 1/2 |

| Cooler / Beverage | 3 | 3 | 3 |

| Rocks | 3 | 3 | 3 |

| Double Old Fashioned | 3 | 3 | 3 |

| Water | 3 | 3 | 3 |

| Wine Large | 1 1/2 | 1 1/2 | 1 |

| Wine Small | 1 | 1 1/2 | 1 1/2 |

| Beer | 3 | 3 | 3 |

| Martini | 1 1/2 | 1 1/2 | 1 1/2 |

| Margarita | 1/2 | 1 | 1 1/2 |

| Flute | 1 | 3 | 1/2 |

| Shot Glass | 1/2 | 1/2 | 1/2 |

| Dessert Dish | 1 1/2 | 1 1/2 | 1/2 |

| Carafe | 1/2 | 1/2 | 1/2 |

| Pitcher | 1/2 | 1/2 | 1/2 |

| ITEM TYPE | HOTEL / FINE DINING | FAMILY / RESTAURANT |

|---|---|---|

| Teaspoon | 5 | 4 |

| Dessert / Soup Spoon | 2 | 2 |

| Table Spoon | 1/4 | 1/4 |

| Iced Tea Spoon | 1 1/2 | 1 1/2 |

| Demitasse Spoon | 2 | - |

| Boullon Spoon | 2 | 2 |

| Table Fork | 3 | 3 |

| Salad / Dessert Fork | 1 1/2 | 1 1/2 |

| Cocktail Fork | 1 1/2 | - |

| Table Knife | 2 | 2 |

| Butter Knife | 1 1/2 | 1 |

Flatware is rust resistant, but not rust proof.

Knowing what causes flatware to rust is half the battle in keeping corrosion in check. Here are some things that cause rust on flatware.

Knives tend to be the biggest challenge when it comes to corrosion.

Bar Keepers Friend, or similar product (soft cleanser), are best to use to clean rust from flatware.

The oxalic acid breaks down and removes rust stains.

Cleaning Tips;

The short answer:

18 refers to 18% chromium content, and the other number refers to the percentage of nickel content. There is no difference between 18/8 and 18/10. It's purely marketing. 18/0 however, has no nickel content, which means it won't keep its silver-like shine over the years.

The long answer:

The numbers 18/0, 18/8 and 18/10 refer to the percentages of chromium and nickel in the stainless steel alloy. The "18" refers to the chromium content, which gives flatware its rust-resistance properties, and the "8" or "10" refers to the nickel content, which gives it its silver-like shine and some rust-resistance. There is a lower quality flatware commonly available called 13/0 or 13 Chrome, which simply has 13% chromium content.

These numbers are merely "nicknames" for the lay person to use, and are only used for marketing efforts by flatware manufacturers. When a manufacturer purchases stainless steel from a steel mill, they purchase stainless steel Grade 304, which has a range of 18-20% chromium, and 8-10% nickel content. Grade 304 in flatware is usually at the lower end of that range. To keep the cost down, steel manufacturers will make grade 304 with 8.2% nickel, which clears the legal hurdle of calling it 18/10. What does all this mean? It means that there is no difference between 18/8 and 18/10 stainless steel in flatware. The difference between the two is purely a marketing effort.

18/0 however, is a different story. It's made from the "Grade 400 series", which contains no nickel.

Flatware – How do you know if flatware is magnetic?

However, for flatware retrievers, you should look for items labeled as 18/0. This means that the flatware has no (0%) nickel content, but it will be magnetically attracted to a flatware retriever. Keep in mind that while this grade of flatware is more economical, it won’t have as much shine to its finish as the higher nickel content 18/10 grade of flatware.

Proper care and maintenance of your G&A furniture will help add longevity to the product as well as keeping it looking new. We will discuss the proper treatment for your furniture by category.

Use only warm soapy water to clean wood chairs, wood barstools and wood table tops. A mild soap such as dish washing liquid is preferred. Do not use de-greasers, cleaning chemicals or a mixture of water and bleach/ammonia. Those chemicals will harm the seal-coat which is applied as a final protector of the wood’s surface. Avoid using any citrus based products as the citrus can dissolve the clear coat and/or stain. Below, is a picture of a wood table top that was cleaned with chemicals.

Use only warm soapy water to clean wood chairs, wood barstools and wood table tops. A mild soap such as dish washing liquid is preferred. Do not use de-greasers, cleaning chemicals or a mixture of water and bleach/ammonia. Those chemicals will harm the seal-coat which is applied as a final protector of the wood’s surface. Avoid using any citrus based products as the citrus can dissolve the clear coat and/or stain. Below, is a picture of a wood table top that was cleaned with chemicals.

There are products that will safely clean wood surfaces which are readily available. Murphy’s Oil Soap or similar products are recommended.

Always dry the furniture after cleaning.

To ensure that chairs and barstools are structurally sound, they should be checked on a regular basis. Make sure that bolts and screws are tightened. Also, be sure the glides are secure and replace any that are worn.

If chairs and barstools are turned over for floor cleaning, be careful not to damage the rear posts on the table edges.

Wipe dry any liquid spills on tables immediately. Use coasters under glassware, pitchers, etc. to prevent ‘sweat’ rings from forming.

Do not place any hot items directly on the table to include carafes, plates, and small skillets, etc. Heat shielding mats will work only to 250 degrees which is harmful to the table’s surface. Consider trivets to protect table surfaces.

Metal chairs and barstools should be cleaned with warm soapy water only. Again, as with wood products, a clear coat is used to protect the surfaces and this will be eroded with the use of chemicals. After using the water solution, dry the chair to prevent rusting. For particularly tough stains, you can use a commercial cleaner like 409. After the stain is removed, rinse with warm soapy water and dry thoroughly.

Aluminum chairs and barstools can be cleaned with warm water. If they are installed near a pool or salt water, hosing them down on a weekly basis will prevent pitting of the aluminum which can occur in these environments.

Again, warm soapy water is the cleaning agent which should be used to clean table bases. Dry the base after cleaning.

Check table glides to make sure they are secured to the base. Adjust them so the table is level.

The warm soapy water is the solution that should be used for cleaning.

Outdoor tables should not be exposed to direct sunlight for extended periods of time.

Our Aluminum TA series should be dried thoroughly after cleaning. These table must be stored right side up: not sideways on its edge or upside down, especially when it rains.

Refrain from using stemmed glassware on our ST Series of tables. They can cause damage to the surface.

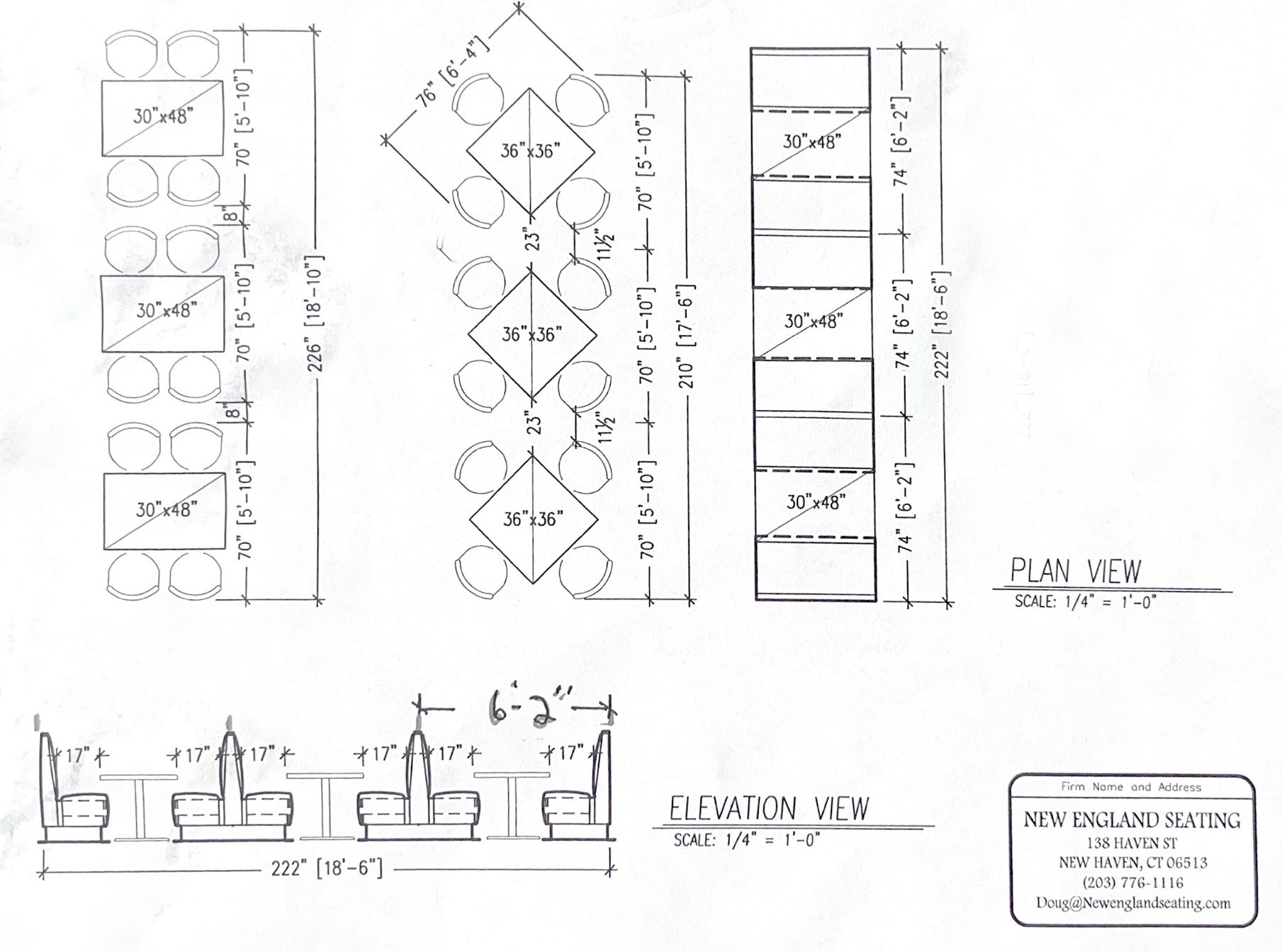

Single Booth – One booth bench. Sits up to two people comfortably side by side.

Double Booth – Sits up to 4 people with 2 people sitting side by side and 2 more back to back.

½ Circle Booth – Standard dimensions are 48” x 90” x 48”. Can seat 4 people.

¾ Circle Booth – Standard dimensions of 48” x 90” x 90” x 48” can seat 6 people.

Wall Bench/Banquette – Available in various lengths.

L-Shape Booth – Mostly used in corners and allows for optimal use of space.

Deuce Single Booth – Similar to that of a single booth but measures 30” instead of 48” long. Known as a single person booth (sits 1 person).

Deuce Double Booth – Measures 30” long, in contrast to the standard double booth’s 48” length. Allows two people to sit back-to-back.

CONSIDER THE AMOUNT OF AVAILABLE SPACE WHEN CHOOSING YOUR BOOTH SIZES

When deciding the amount of space available in your restaurant for choosing the booth sizes, there are a few factors to consider. Here are some key points to keep in mind:

Layout and Space Planning: Start by assessing the overall layout and dimensions of your restaurant. Consider the available floor space, the shape of the dining area, and any architectural features or limitations that may impact booth placement.

Seating Capacity: Determine the desired seating capacity of your restaurant. Consider the number of guests you aim to accommodate during peak times. This will help you decide the number of booths needed and their sizes.

Comfort and Spacing: It is crucial to prioritize guest comfort. Allow enough space between each booth for comfortable movement and ease of sitting down and standing up. The typical distance between tables or booths is around 18-24 inches, but this may vary based on your specific needs and local regulations.

Table Placement: Determine the placement of tables or other seating options in addition to booths. This will help you strike a balance between booth and table seating, maximizing the use of space while ensuring customer preference and comfort.

Top & End Caps –The caps are placed on the sides and top of a booth to cover the frame. Upholstered caps are standard but you can also upgrade to solid wood / laminate caps. When measuring the booths dimensions the height and length include the top and end caps.

Head Roll – A cushioned, upholstered component situated at the top of the booth, serving to enhance comfort.

Crumb Strip – Measuring 1 1/2" in width, it is specifically designed to be placed between the back of the booth and the seat. Its primary purpose is to facilitate effortless cleaning.

When placing two booths that are facing each other, the minimal spacing between booths from one end of a booth to the other should be 70" allowing for a table that’s 24" wide. The wider the table the more space between the booths will be required.

A standard single booth measures 48” in length and 24” in depth. A double booth is 48” long and 49” deep. Dimensions vary by booth type.

Spence Wells Associates

PO Box 159

East Killingly, CT 06243